Modular Bakery System

Our Modular Bakery System is unique,. It has been specially designed for use in bakeries and confectioneries where products are baked on trays or in tins. The system is suitable for producing a wide range of products including the many varieties of bread (buns, rolls and loaves), pizzas, pies, biscuits and full range of cakes (cupcakes, muffins, sheet cakes), cookies and pastries. Mixed production can be accommodated within the full system.

Let’s start building

Each Modular Bakery System is custom-designed according to the requirements of the products our customer wants to produce. The required types and amount of modules is determined whether or not certain processing steps are needed such as proofing, baking and cooling, and if so, how long should your product remain in these processing steps. Furthermore, the amount of modules is also determined by your tray configuration and capacity requirements.

Cooler Section

Using two-stage filtered, 100% outside air, we are able to quickly cool down your products, while keeping your bakery cool.

Deepcooler Section

When additional cooling is required, conditioned air can be recirculated inside the Deepcooler Section.

Vacuum Cooler

Cool down any product in a matter of minutes (including bread loafs), even when they are placed in baking tins!

Proofer Section

Control your proofing temperature and humidity, using our advanced Proofer Sections.

U-Transport

Eliminating manual rack movement by incorporating our U-transport modules.

Oven

At the core of our Modular Bakery System, is the Oven Module.

Loading/Unloading

Automate rack loading using our advanced Loading and Unloading Modules

Cooler Section

The Cooler Section consists of 2 to 5 Cooler Modules, and is used where hot products need to be cooled down. Ambient, outside air, is filtered and passed over the products, before it is expelled to the outside again. The air temperature inside the Cooler Section is controlled using a set of mixing valves, but can't be set to a lower value than the outside air temperature.

If additional cooling, or lower temperatures, are required, multiple Cooler Sections can be incorporated, or one or more Deepcooler Sections can be added to an existing Cooler Section.

Deepcooler Section

The Deepcooler Section consists of 2 to 5 Deepcooler Modules, and is used when additional cooling is required. For this, we use a recirculation system, in which air is continually recirculated over a cooling coil / evaporator. This allows for much lower temperatures, and even more cooling.

Vacuum Cooler

By placing the racks with products in a near vacuum environment, we are able to greatly reduce the required cooling time, which reduces the risk of bacterial growth during cooling.

Using the heat from the products itself, we are able to achieve a reduction in cooling time by as much as 20x.

Proofer Section

When proofing is required, one or multiple Proofer Sections can be incorporated into the Modular Bakery System.

Each Proofer Section can hold anywhere from 1 to 8 racks, in either a single- or multi lane configuration.

Using our in-house built stainless steel sandwich panels, which can optionally be fully welded on the inside, we guarantee an extremely hygienic environment for your products.

Air conditioning is done using externally placed Air Handling Units, which are also constructed out of stainless steel sandwich panels, and comprise cooling and heating elements (fully stainless steel heat exchangers). Humidity can be controlled using direct steam injection, or through means of ultrasonic misting.

Whether you are looking for a short proof time, or a very long proof time of multiple hours for long shelf life products, we have a solution for you.

U-Transport

The U-transport modules are used whenever racks need to be moved sideways or vertically. They allow for a continuous and automated rack movement through the Modular Bakery System.

The U-Transport module is constructed using stainless steel panels, and typically includes inspection windows. Furthermore, they include roll-up doors, to allow easy access into the System whenever sanitation or maintenance tasks need to be carried out.

Oven

Our Oven Modules are the heart of each Modular Bakery System. Depending on the requirements, we can incorporate as little as 2 or as many as 12+ Oven Modules inside one System. As each Oven Module is independently controlled, it is very easy to implement a bake curve.

The Oven Modules are typically gas fired (natural gas or LPG), but can also be heated using oil or electricity.

Air is continually passed over the products using adjustable air slots at each level.

Steam injection and dewpoint control available as an option.

Loading/Unloading

Using our automated Loading System, we are able to receive trays from a make-up line and automatically place them inside our racks, completely eliminating manual tray handling.

Once the entire process is complete, the racks are presented at our automated Unloading System, where they are automatically pushed out of the rack, after which they are discharged onto an outfeed conveyor.

Trays can be received and discharged at any level, even if this is on a different floor.

Discover opportunities together, let’s bake success!

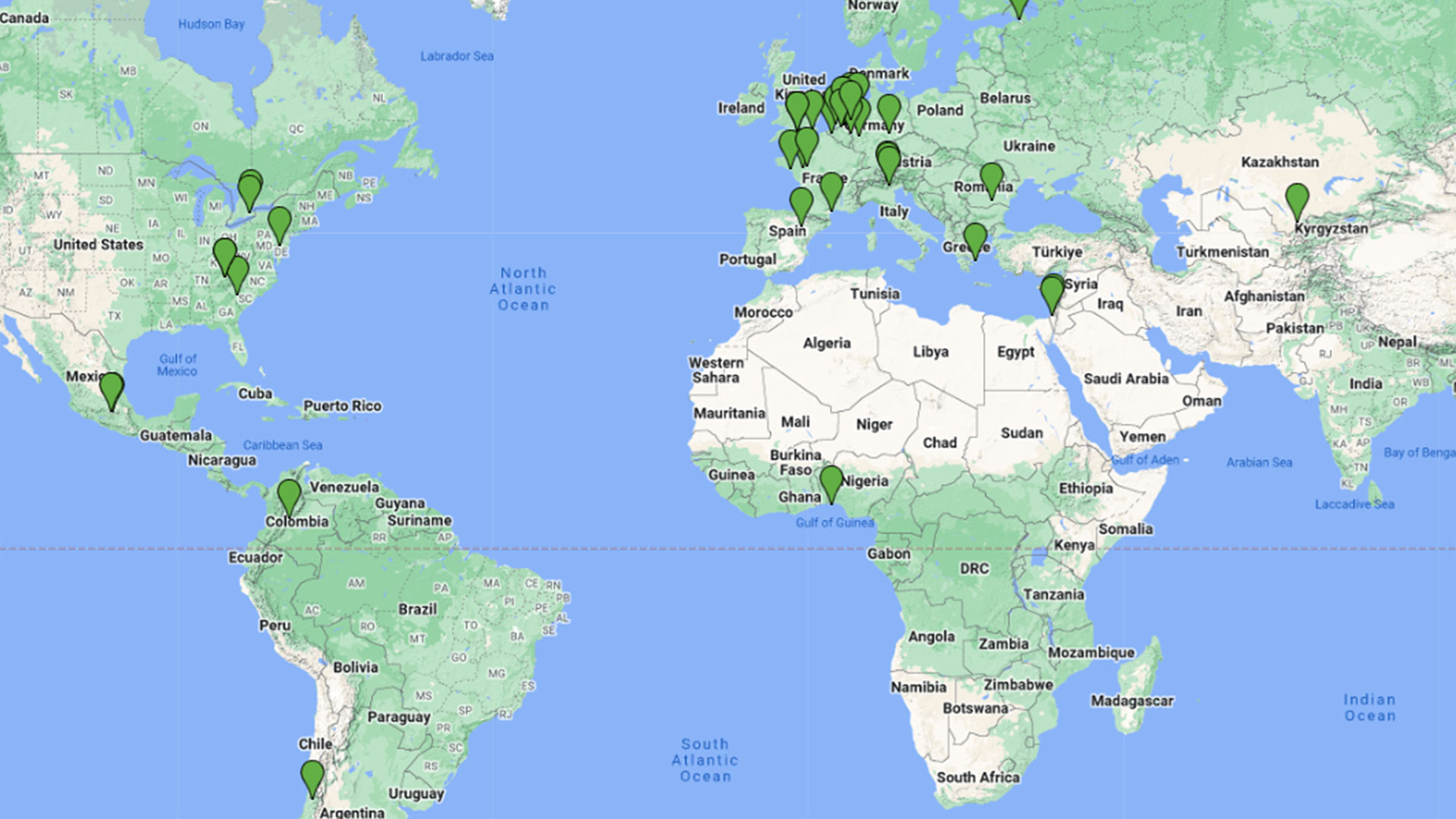

Worldwide representation, combined with our main office in Tilburg, the Netherlands, means we can quickly get in touch to discuss your next project.