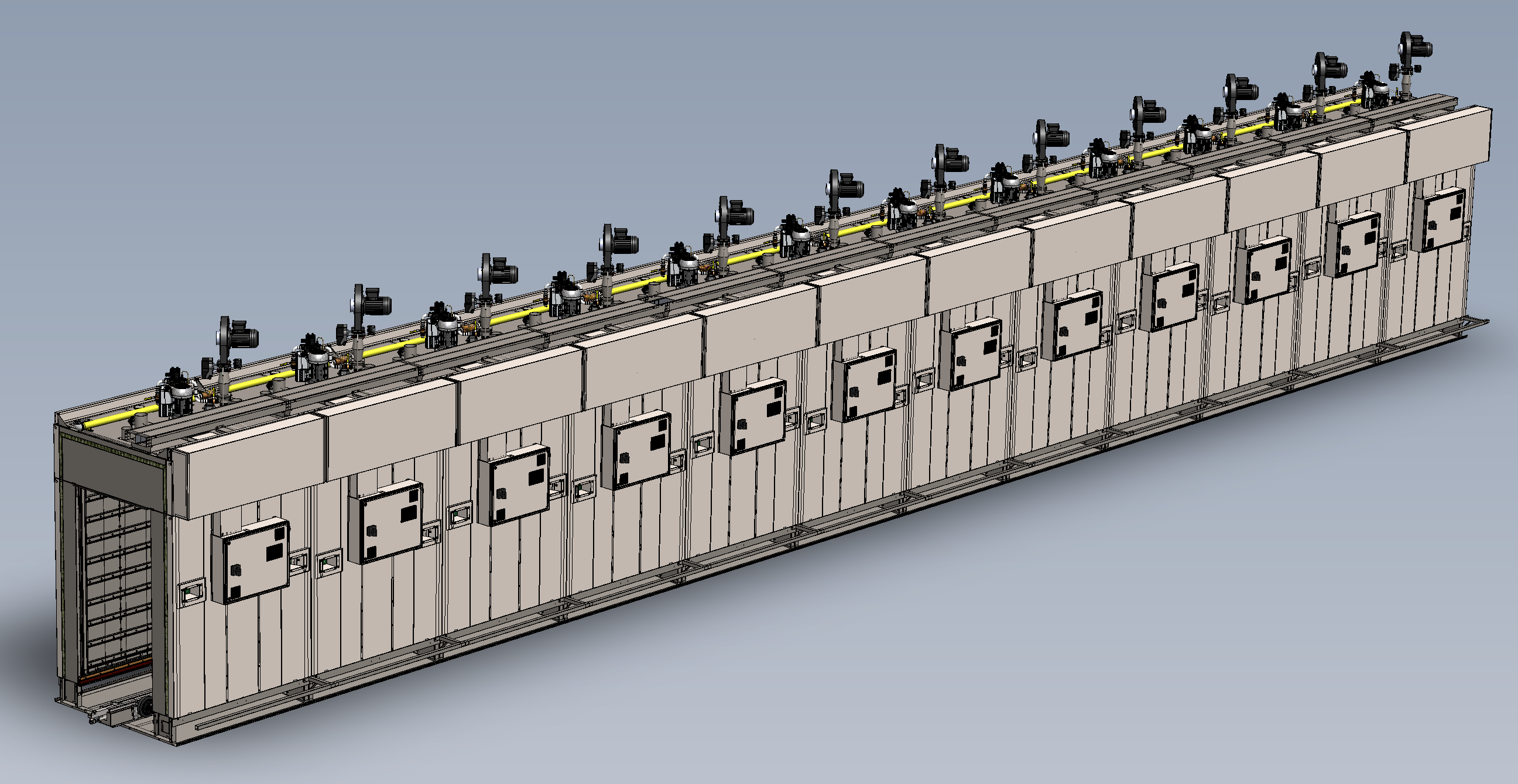

Tunnel Rack Oven System

The Dijko Tunnel Rack Oven System is unique. It has been specially designed for use in bakeries and confectioneries where products are baked on trays or in tins. The system is suitable for producing a wide range of products including the many varieties of bread (buns, rolls and loaves), pizzas, pies, biscuits and full range of cakes (cupcakes, muffins, sheet cakes), cookies and pastries. Mixed production can be accommodated within the full system.

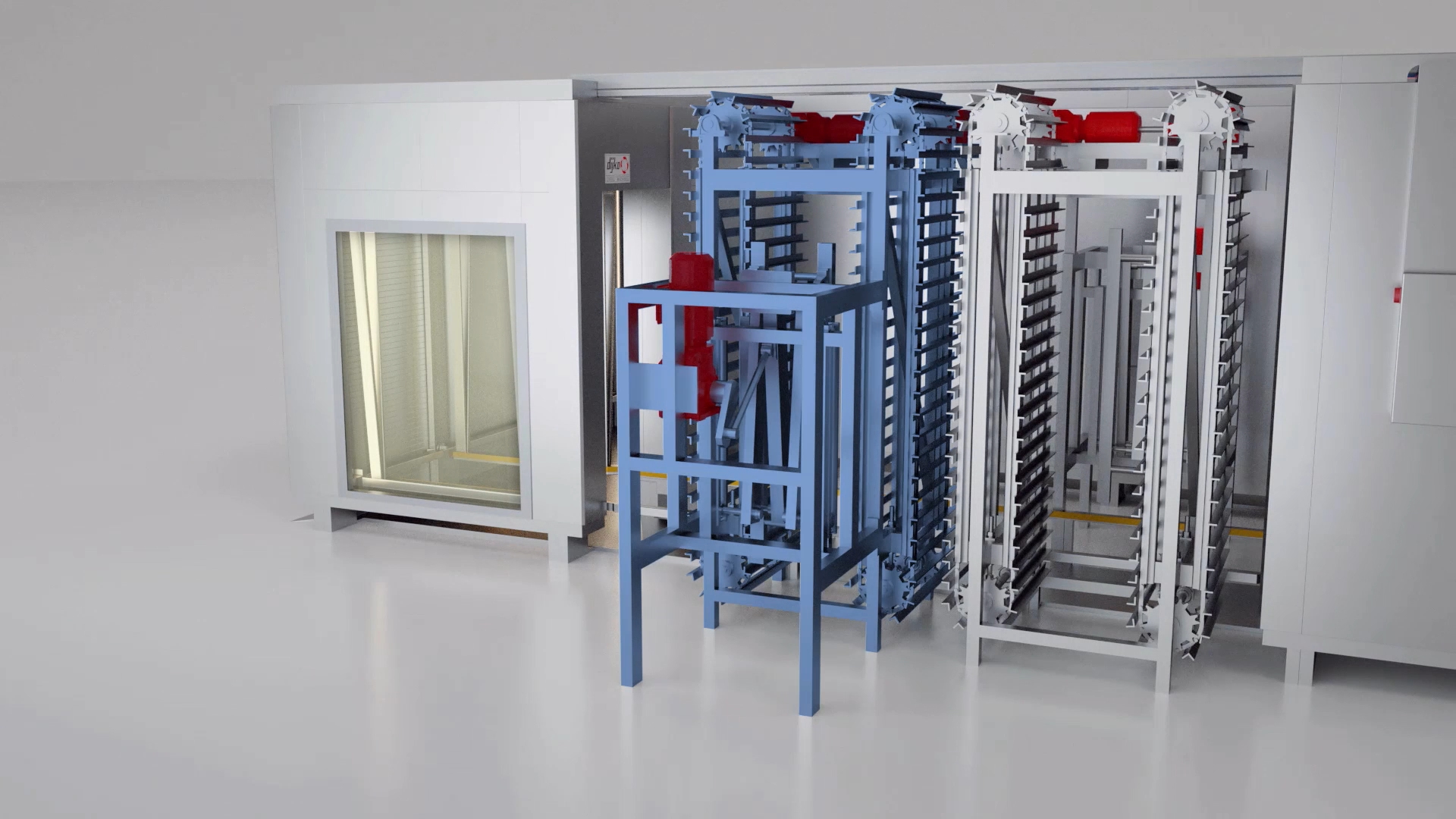

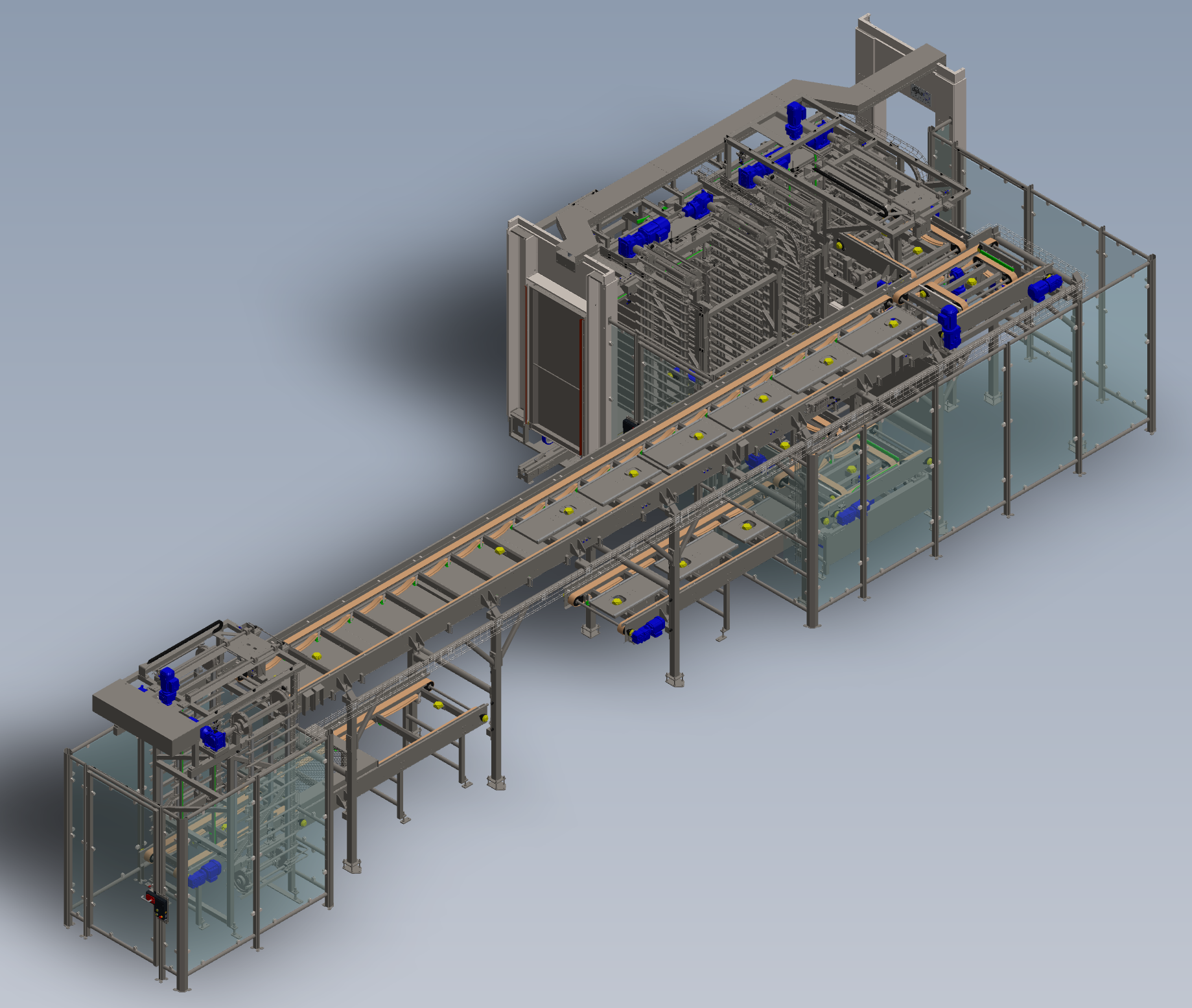

The Tunnel Rack Oven System is of modular construction and can be used whenever baking temperatures up to 300 °C are needed. Appropriate modules can be supplied for proofing, baking, (vacuum)cooling, freezing and automatic tray loading and unloading. Furthermore, additions can be made to incorporate additional product handling, such as eggwashing, water cutting, or lidding of trays (typically all done after proofing).

Typical production capacities for the Tunnel Rack Oven System can range anywhere from 250 kg/hour to 5.000+ kg/hour, but are highly dependent on the products being produced on the system.

Rack and Tray Configuration

The Tunnel Rack Oven System uses trays and racks to transport your products through the system. We can accommodate a wide variety of tray sizes, ranging anywhere from 460×660 mm (standard 18″×26″), to massive trays of 920×1500 mm. A few typical tray sizes that are commonly used in our system include:

- 800×400/600/800 mm

- 900×600/900 mm

We are always willing to look into the possibilities of matching our system to your existing trays and equipment, eliminating the need to renew them.

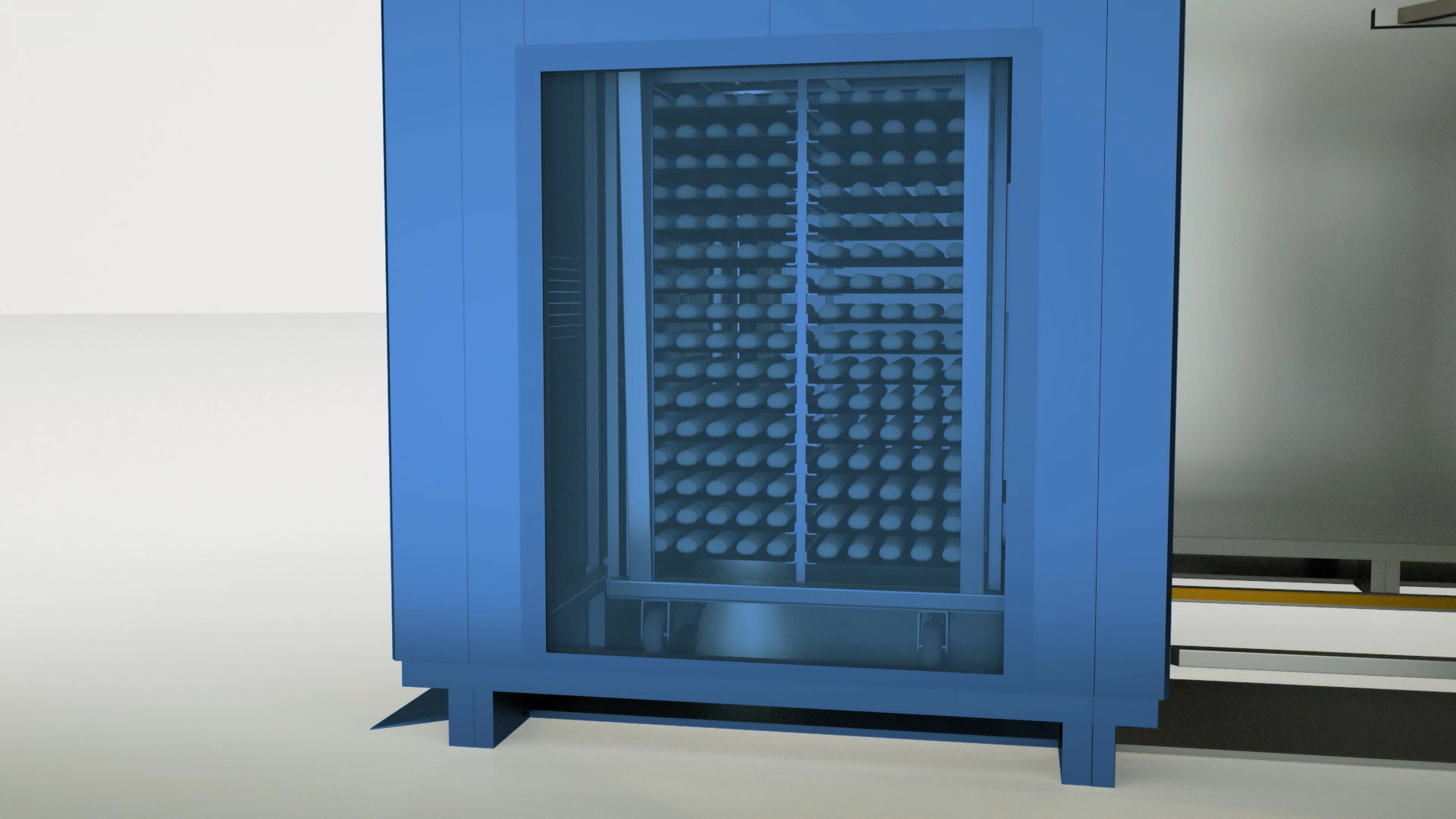

The trays are placed inside special racks, that form an integral part of the Tunnel Rack Oven System. Each rack is exactly one module long, and forms the front, back and bottom of each module. Racks are placed back to front, sealing off all modules. Each rack is able to hold between one and four columns of baking trays, depending on the tray size.

The amount of baking levels inside the Tunnel Rack Oven System depends solely on your finished product and tray height combined. A typical amount for the number of baking levels ranges between 8 and 16, but systems have been designed for as many as 40 levels. This ensures a minimal use of floor space, often as little as 2O% of that required for a conventional traveling oven of similar output. This saves valuable space, which is often a major concern for businesses who are expanding their production.

System Overview

The Dijko Tunnel Rack Oven System can comprise of multiple modules and sections, which will be described below.

01. Loading Tower

Loading of the trays into the racks can be done using an automating loading system. This system will accumulate the required amount of trays (equal to the amount of baking levels), after which they will be pushed into an empty rack.

The loading tower is able to receive trays at all possible heights, even from other floor levels.

02. U-Transport

The U-Transport makes the racks move to a parallel lane, and is typically used when limited length is available, or when a fully automated system is in place.

Depending on the requirements, the Tunnel Rack Oven System is equipped with zero, one or multiple U-Transport modules. A system with zero U-transport modules is a system with only one lane, in which the racks need to be presented (by hand) to the entrance. Rack transport through the system is then automated. After the process is completed, a rack will automatically be ejected after the last module, where it will be taken by hand for further processing. Loading and unloading of trays can still be automated in this system.

A system with only one U-transport module is similar to the previous system, with the only change being that the system now comprises of two parallel lanes, which are linked by a U-transport module. This solution can be chosen when there is not enough length available or when it is convenient to return the racks to the infeed position. Loading and unloading of trays can also be automated in this system.

In a fully automated system, two U-transport modules are used, on either end of the Tunnel Rack Oven System. This enables a continuous loop, in which the racks are automatically transported through the system. No manual rack handling is required. Loading and unloading of trays in this system is always automated.

The U-transport is fully made from stainless steel, and has two roll-up access doors that allow for the racks to be taken out of the system during maintenance and/or cleaning.

03. Proofer

When the Tunnel Rack Oven System is utilized to produced proofed products, such as bread and danish pastry, a proofer section is required.

The proofer section can comprise of multiple zones where, in each zone, the temperature and humidity can be independently set. Each zone holds a minimum of 1 rack. Heating and cooling inside each zones is done via multiple stainless steel heat exchangers, hooked up to an available hot water and glycol source. When these are not available, Dijko can include hot water and glycol cooling generation using a hot water boiler and water chiller.

Humidity control is done through a combination of steam injection (using an available steam source or alternatively using ultrasonic steam generators) and dehumidifying.

The proofer section typically holds one lane of racks, in which all racks are positioned front to back. When very long proof times are required, we have the option to have multiple parallel lanes side by side (systems up to 4 proofer lanes wide are possible).

04. Handling

When post-proof and pre-bake production steps are required for your products, such as bread scoring/egg washing/product decoration, the Tunnel Rack Oven System offers this flexibility.

Depending on the tasks to be carried out, we can either remove the trays completely from the racks and put them on a secondary tray loop for additional processing or we can carry out the tasks in place. The latter option is typically suggested for bread scoring, which can be done using an in place scoring machine. This machine automatically pulls one level of trays out of the rack, carries out the scoring using water jet nozzles, and then places the trays back into the rack. The scoring path can be defined freely for an unlimited amount of scoring patterns.

If more elaborate tasks are required, a robot can be used.

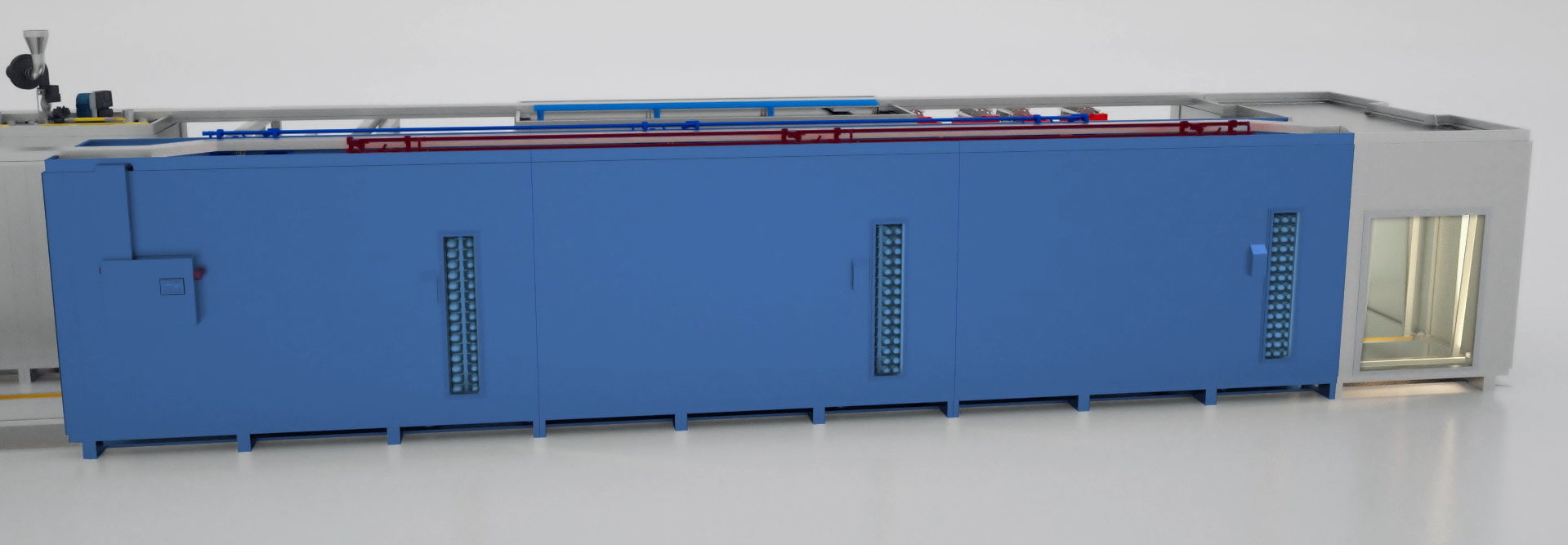

05. Baking

Each oven module is a self contained entity, which comes fully pre-assembled with its own burner system, air intake and exhaust system, air circulation system and PLC controls.

Air distribution over the products is fully adjustable, using adjustable side air slots. Furthermore, air speeds are fully adjustable using frequency controlled motors, with a self developed circulation fan.

As each oven module is fully adjustable with regards to temperature, fan frequency and exhaust damper position, a bake curve can be created when more than one oven module is used.

Optionally, the oven modules can be equipped with dewpoint control and steam injection.

The oven modules come standard with inspection windows (1 or 2, depending on module length) and a fully stainless steel interior and exterior.

By utilizing multiple baking levels inside each oven module, a baking surface in excess of 20 m2 can be achieved on a mere 3 m2 module footprint (using 800×800 mm trays, with 32 trays per rack/module). This makes the Dijko Tunnel Rack Oven System one of the most space friendly options out there.

System Examples

The following images show a brief overview of systems that have been produced by Dijko over the years.

[ngg src=”galleries” ids=”1″ display=”thumbnail” thumbnail_crop=”0″]

Address

Dijko Ovens BV

Dr. Hub van Doorneweg 44

5026 RA TILBURG

Contact Us

Phone:+31 (0)13 594 22 11

Fax: +31 (0)13 594 22 12

E-mail: info@dijko.com

Opening hours

Monday - Friday: 08:00 - 16:30

Saturday: closed

Sunday: closed