Cakes

Using our solutions for cake production, we have designed an delivered a multitude of Systems worldwide. These can be used to produce regular (sheet)cakes, cupcakes, muffins and brownies, with capacities reaching as high as 4.000 kg/hour.

Typical configuration

A typical cake line consists of multiple Oven Modules and Cooler/Deepcooler Sections, with the option to incorporate Vacuum Cooling. Furthermore, Freezing Sections can also be incorporated. Full automation using our rack loading and unloading systems is always possible.

Example layout

Muffin production

This system is located in the United Kingdom, and is used to produce up to 12.000 muffins per hour.

After baking (using 6 Oven Modules), the muffins are cooled using a total of 4 Cooler Modules and 4 Deepcooler Modules. The system utilizes full automation.

Example layout

Sheet cake production

This system, located in Mexico, is used to produce two types of products, namely “Rosca de Reyes” or King’s bread, and sheet cakes. When running production of Rosca de Reyes, 6 Proofer Modules are used, as well as 10 Oven Modules and a two-chamber Vacuum Cooler. When the sheet cakes are being produced, the Proofer Modules are bypassed, and only the Oven Modules and Vacuum Cooler are in use. This makes this line extremely flexible.

Automatic loading and unloading is also included.

Discover opportunities together, let’s bake success!

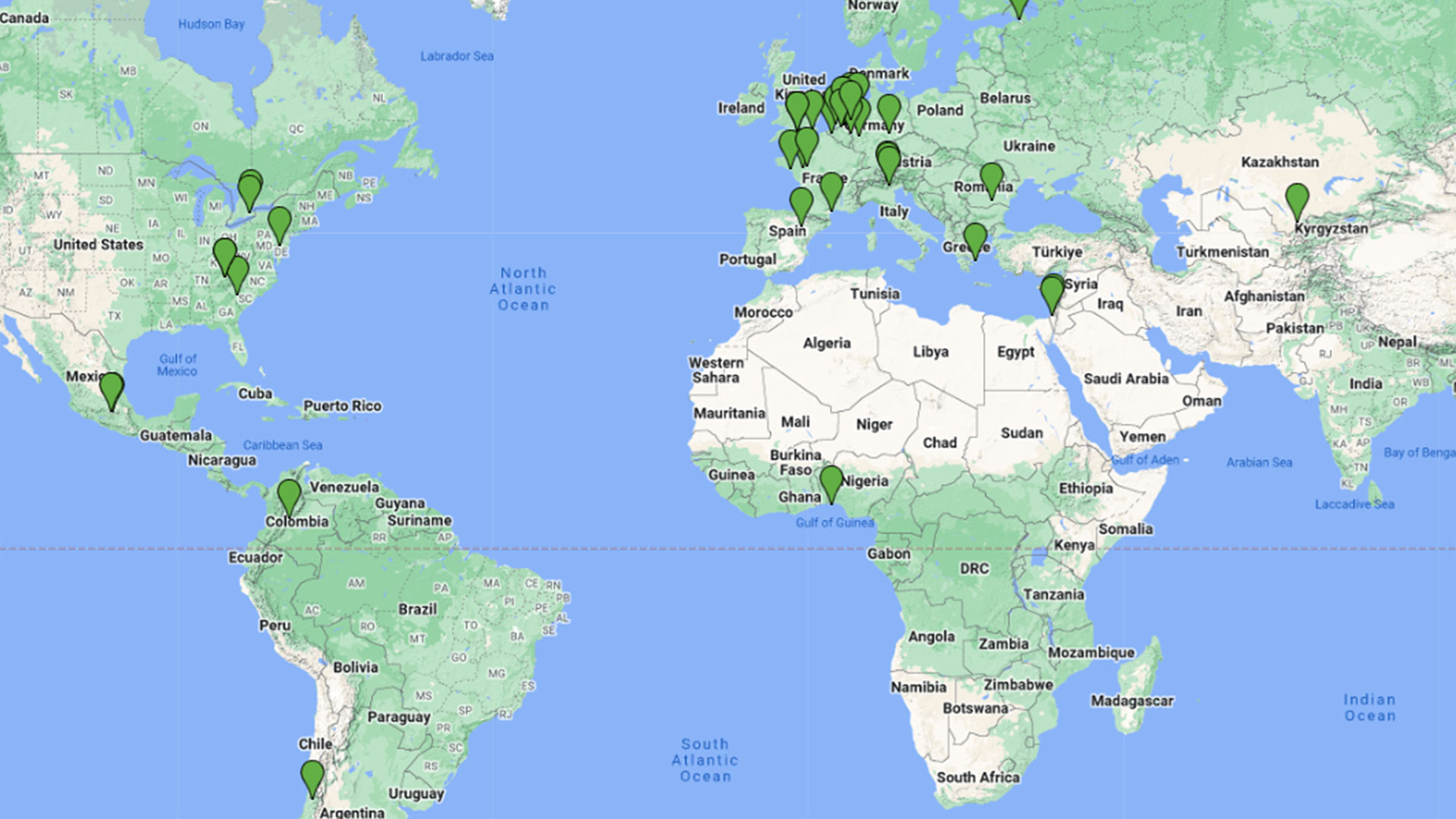

Worldwide representation, combined with our main office in Tilburg, the Netherlands, means we can quickly get in touch to discuss your next project.

Other applications

Curabitur blandit tempus porttitor. Aenean eu leo quam. Pellentesque ornare sem lacinia quam venenatis vestibulum. Nullam id dolor id nibh ultricies vehicula ut id elit.

Bread

Using our Modular Bakery System, capacities can range from anywhere between 500 kg/hour to 5.000kg/hour.

Pastry

Our solutions can be used to produce regular pastries, but also long-shelf-life pastries.

Cookies

Using our solutions for cookie production, both semi- and fully automated.